Dimensional Measurement, Inc. (DMI) offers a variety of vision inspection and non contact inspection services, which are useful in measuring free-form parts and become necessary when measuring flexible or fragile parts. Depending upon the part submitted and the required data output, we can utilize the equipment that best suits your application – or combine our capabilities to produce the desired final result. These services include:

- 3D Laser Scanning

- Reverse Engineering Services

- Camera based Vision Inspection

Non Contact Inspection:

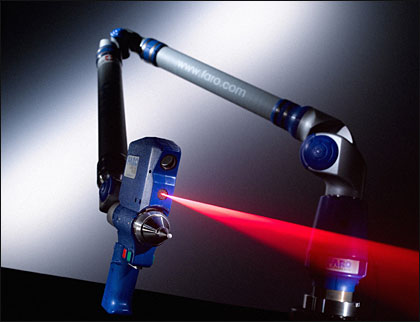

3D Laser Scanning or Laser Digitizing utilizes a beam of laser light to capture the physical shape of the subject part, and produces a digital image, or point cloud. Laser digitizing is among the most versatile non contact inspection services because it is highly portable, suitable for a wide range of part sizes, and capable of obtaining a

large amount of data. Laser Scanning can also be used in tandem with DMI’s contact CMM measurement methods to create reverse engineering solutions that neither measurement method can provide on its own. DMI’s 3D laser scanning services can be performed either at our facility in Wixom, Michigan, or our metrologists can come to your

facility, which is exceptionally helpful for large or sensitive parts.

The 3D Laser scanning process can provide either 3D or 2D (cross section) results to compare scanned parts to their CAD models. A 3D comparison provides a color map of the CAD model displaying deviations between the 3D model and the physical part. A 2D comparison provides a whisker plot and deviations shown by both color and length of the whisker. Both provide a very complete picture of the

part’s condition.

Another important non contact inspection method is camera-based vision inspection, also commonly referred to as video inspection or optical CMM inspection. This method is best suited to thin or soft parts, or to items that cannot be probed easily, such as a very small inspection can be extended to include features that are resistant to other inspection methods by using an impression or casting compound to mold the area, then inspecting the mold of the part.

Laser Scanner picture copyright and courtesy of Faro.